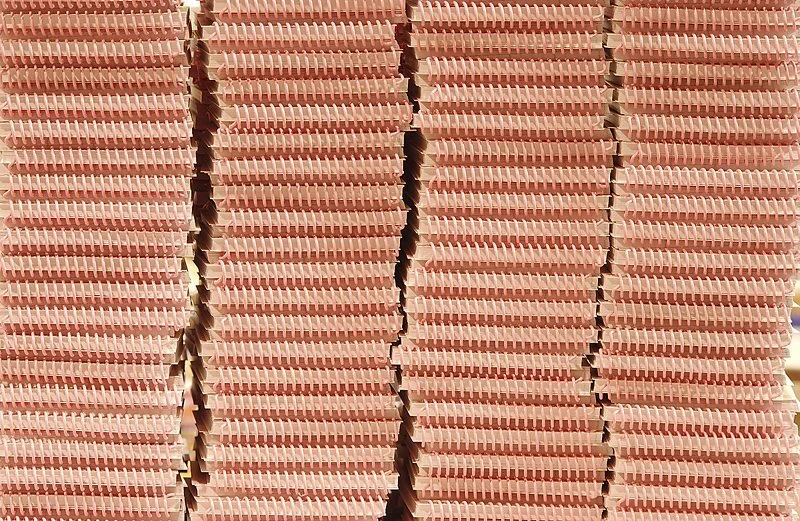

Waste not want not, stock piled

Waste not, want not

When we think of inventory, we typically think of the manufacturing industry, but businesses in any sector have inventory: Food, retail, service, government, not-for-profit, professional associations...name the business and it's a guarantee that the business deals with inventory. Inventory is necessary for business operations, but when supply exceeds demand, problems arise, especially in the organization's bottom line.

Take forms and publications as an example. Many organizations produce both. Now think about how many forms and publications your organization has stockpiled not only in one department, but perhaps in several. Excess inventory hurts not only your bottom line, but your reputation, as well. If you're a bank with piles of loan applications lying around your office, what does that say about you to the customer? Or if you've got outdated stationery stock or computer equipment lying around your workplace, what image are you portraying to not only your customers, but to your staff, as well? On top of this, the "clutter" reduces employee morale and inhibits creativity and excellent work performance.

Having exactly the right amount of inventory to meet your turnover rate is possible. Start by determining root causes of the excess inventory and then identify solutions to eliminate the root causes. Some root causes may include long lead times, poor forecasting accuracy, quality problems, or design obsolescence. Eliminating root causes of low-turnover inventory will prevent arbitrary year-end reductions in inventory investment.

Organizations with outstanding inventory performance also excel on other dimensions such as customer service, delivery, and productivity. And if your organization is not exceling in those areas, then it is underperforming and losing money.

Stock piled

Would you invest your money in a financial institution that offered you a negative 25 percent interest rate? No, you wouldn't do that, but many organizations are quick to purchase supplies that they "may need" sometime soon. This is the same as investing your money in the negative return.

Carrying stock is expensive, usually 20 to 40 percent of the average value per year. It not only costs to purchase, but it consumes valuable floor space in the office or may require large warehouses. It also increases material handling costs and large stocks require computer systems for tracking and control.

Inventory management has seen more emphasis in the past decade with the development of various inventory control and management techniques. However, reducing stockpiles of inventory is not just about reducing the amount of orders. It includes reviewing the process of inventory management, as well. It is about developing a self-sustaining approach rather than just looking at monetary gains in the short-term.

To get a better handle on your organization's inventory and manage your stockpiles, apply the Deming cycle (Plan-Do-Check-Act) to evaluate your organization's requirements. This includes observation, preparation, and planning of Lean initiatives (Plan), implementation (Do), measurement and assessment of the implementation (Check), and continuous improvement of the process (Act).

Don't underestimate the cost/value of your inventory. It can be the one thing that is contributing to decreased profits.